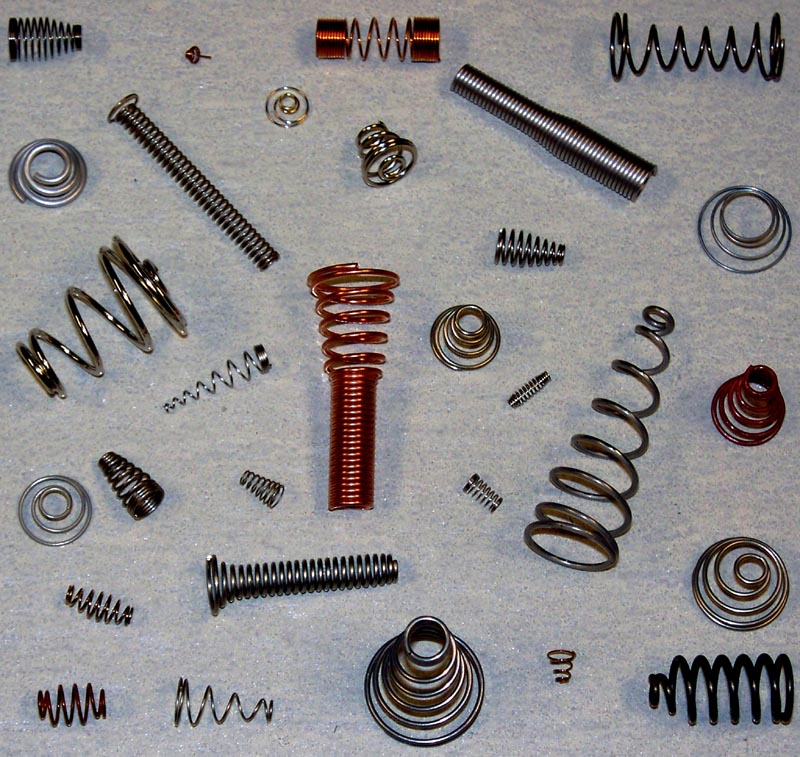

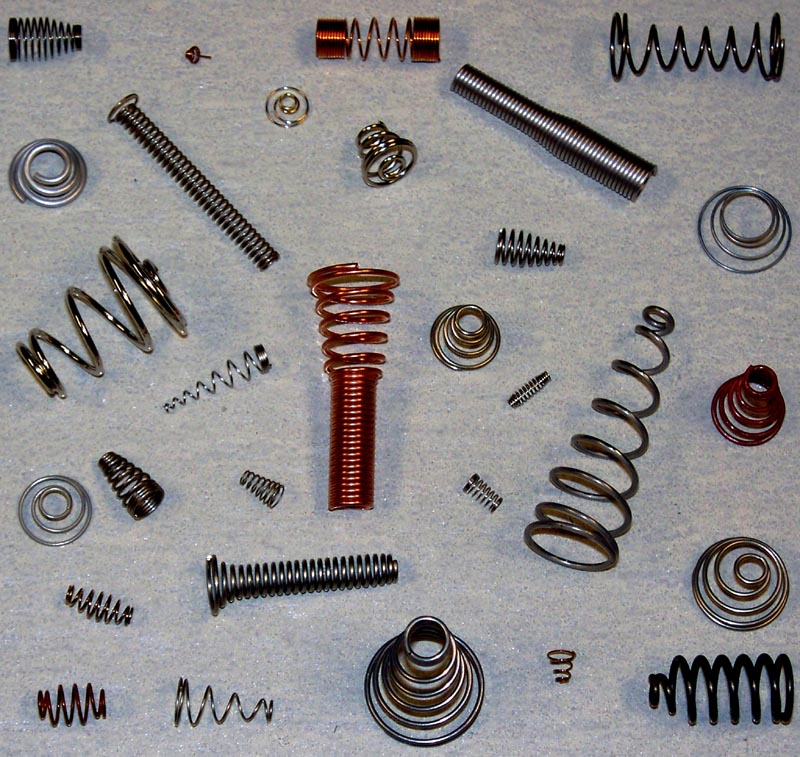

Hourglass or Concave - Tapered so that both ends are larger than the middle. These springs can have some of the same advantages as a conical spring with the added advantage that they are symmetrical. The enlarged end coils may also help keep the spring centered on a larger diameter hole.

Variable Pitch - Wound with a varying amount of space between the coils. This technique can be used to produce springs with a non-linear load vs. deflection curve, or to add closed coils in the center of the spring to reduce tangling.

Preset – Springs that will operate at a stress level that exceeds the elastic limit of the material can be preset by compressing a spring to solid height. This process removes any permanent deformation due to exceeding the elastic limit of the material and builds in beneficial stresses near the wire surface, with an apparent increase in the elastic limit.

At Templeman, we can produce all of the above types of compression springs to your exact specifications. We also stock a large selection of straight compression springs and a limited selection of conical compression springs. We are well equipped to work within the following size ranges:

- Wire Diameter – 0.004" [0.1 mm] to 0.080" [2.0 mm]

- Coil Outside Diameter – 0.030" [0.75 mm] to 1.75" [45 mm]

- Free Length – Up to 16" [40 cm]

- Spring Index – 4 to 24 (Mean Coil Diameter divided by Wire Diameter)